Picture this: you’re working in a bustling kitchen, surrounded by French fry machines splattering oils and water splashing from the sinks onto the floors, making them slick as ice. One minute, you’re standing happy and tall, the next, you’re slipping into a body cast and a long recovery. Enter the unsung hero of the workplace swooping in to save you from slick floors – the slip-resistant safety shoe. But how did safety shoes evolve into the stylish, protective footwear we know today? Take a walk through history and find out.

From Wooden Wonders to Steel-Toed Saviors

The first “protective boots” were from the 18th century and were little more than wooden sabots. These simple shoes, carved from a single block of wood, were the go-to footwear for European peasants. They might not have been the height of fashion, but they did a decent job of protecting feet from falling objects like sharp farm implements. Little did those farmers know their humble wooden shoes would kickstart a revolution in workplace safety. As the Industrial Revolution gained steam, so did the need for better foot protection. Workers were facing new dangers in factories, and those wooden clogs weren’t cutting it anymore.

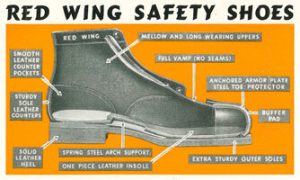

It wasn’t until the 1930s that we saw the modern safety shoes that included arch support, sturdy heels, steel toes, ankle support, and more. Red Wing Shoes Company in Germany started mass-producing these boots, giving workers the upper hand against falling objects and heavy machinery.

The Slip-Up That Changed Everything

But what about slips and falls? These accidents were responsible for a whopping 20% of all workplace injuries. Clearly, something had to be done to minimize these accidents.

In the 1990s Lehigh Safety Shoes had a lightbulb moment when they created the LSR® (Lehigh Slip Resistant) shoe line. It was specifically designed for workers in the hospitality and restaurant industry. These shoes were a game-changer. With their easy-to-clean leather and specially designed soles, they could handle the slippery chaos of a commercial kitchen like a champ. The secret? A tread pattern that channeled liquids away from the soles of the shoes, allowing for better contact with the floor.

The Evolution of Slip Resistance

As workplace safety standards evolved, so did slip-resistant technology. Lehigh continued to innovate, introducing new materials and designs. In 2017 they unveiled the Dragon Grip outsole, taking slip resistance to new heights.

But it wasn’t just about the sole anymore. Safety shoe manufacturers started considering every aspect of the shoe. These shoes became high-tech armor for your feet including everything from puncture-resistant midsoles to heat-resistant uppers. And the best part? They started looking good too! Gone were the days of clunky, ugly work boots. Modern safety shoes come in sleek sneakers to stylish boots, proving that safety doesn’t have to cramp your style.

The Science of Slip Resistance

What makes a shoe slip-resistant? It’s more than just having a rough surface. The magic lies in the combination of the sole material, the tread pattern, and even the chemistry of the compounds used. The ideal slip-resistant sole needs to:

- Channel liquids away from the contact surface

- Provide the right amount of friction against various floor types

- Resist wear and tear from harsh environments

It’s a delicate balance of science and engineering all focused on keeping you upright in the most challenging conditions.

Beyond the Kitchen: Slip Resistance in Every Industry

While slip-resistant shoes got their start in the food service industry, their usefulness quickly spread to other sectors. Today, you’ll find specialized slip-resistant footwear in:

- Healthcare facilities

- Manufacturing plants

- Construction sites

- Retail environments

- And many more!

Each industry has its unique challenges, and shoe manufacturers have risen to meet them. There’s a slip-resistant shoe for every job from oil-resistant soles for mechanics to electrostatic dissipative options for electronics workers.

The Future of Foot Safety

Who knows what the future holds! Manufacturers are exploring new materials, like graphene-enhanced rubber that promise even better grip and durability. Smart shoes with sensors to detect hazardous conditions might not be far off. And it’s about more than just technology. There’s a growing focus on sustainability in safety footwear. Companies are looking for ways to make their shoes more environmentally friendly without compromising safety or comfort.

Conclusion: Stepping Safely Into The Future

From wooden clogs to high-tech treads, the history of slip-resistant safety shoes is a testament to a commitment to workplace safety through human ingenuity. At CrewSafe, we understand the importance of proper safety equipment in the workplace. That’s why we’re dedicated to providing top-quality safety products and fostering a culture of awareness and prevention. So, the next time you lace up your work shoes, take a moment to appreciate the centuries of innovation on your feet.

Sources

- Lehigh CustomFit (2024) 100 Years Of Safety & Innovation – Lehigh CustomFit. Available at: https://www.customfit.me/history/ (Accessed: 29 October 2024).

- Profit Footwear (2022) Safety Footwear A Brief History. Available at: https://profitfootwear.com/blog/safety-footwear-a-brief-history/ (Accessed: 30 October 2024).

- Lemaitre Sécurité (2024) THE HISTORY AND EVOLUTION OF SAFETY FOOTWEAR. Available at: https://www.lemaitre-securite.com/gb/blog/the-history-and-evolution-of-safety-footwear-n18 (Accessed: 30 October 2024).

- Aspida Footwear (n.d.) The History Of Safety Shoes. Available at: https://aspidafootwear.com/stories/the-history-of-safety-shoes (Accessed: 29 October 2024).

- RedWing Shoe Company (1900-present) Explore Key Moments In Our Storied Past. Image Red Wing Safety Shoe –Steel Toe circa 1934. Available at https://www.redwingshoeco.com/history