Quick-service restaurants (QSRs) and food service businesses operate at a relentless pace, serving millions of customers each year. In these high-traffic settings, maintaining impeccable cleanliness is not just a regulatory requirement; it’s the foundation of employee well-being and brand excellence. While businesses can struggle to keep up, the latest wave of robotic cleaning inventions may be the solution to empower operators to meet and exceed these expectations, with the added bonus of streamlining operations and reducing risk.

How Robotic Cleanliness Is Different

The integration of robotic systems in QSRs and food service environments is fundamentally changing how businesses approach hygiene and overall workplace safety. Robots now handle a range of critical cleaning tasks, from scrubbing floors to disinfecting high-touch surfaces. Using technologies such as UV-C light to eliminate pathogens and minimize the risk of foodborne illness, these advancements directly address key safety concerns, including cross-contamination, chemical exposure, and slip-and-fall hazards. All are frequently cited by the Occupational Safety and Health Administration (OSHA) as significant risks, especially in the food service industry.

The Highest Regulatory Standards

Compliance with U.S. government safety regulations is non-negotiable for any business. OSHA’s sanitation standard 29 CFR 1910.141, requires employers to maintain clean, orderly, and hygienic workplaces, provide access to potable water, and ensure safe food handling practices. The Centers for Disease Control and Prevention (CDC) further underscores the importance of rigorous cleaning protocols to prevent the spread of infectious diseases, a focus that intensified after the COVID-19 pandemic.

Key Benefits for Employees and Customers

Robotic cleanliness delivers measurable advantages for both staff and patrons, including helping businesses meet regulatory standards. Some examples include:

- Employee Safety: Robots can protect employees by taking on risky cleaning duties, such as mopping greasy floors, helping prevent slip-and-fall injuries, a leading cause of workplace injuries in restaurants. They can also sanitize high-risk zones, minimizing employee exposure to hazardous cleaning agents. Both support OSHA’s mandate for safe working conditions.

- Sanitation: Robots can utilize UV-C and other advanced disinfection methods to reduce viral and bacterial contamination, aligning with CDC recommendations.

- Operational Efficiency: Using robots to automate repetitive cleaning tasks, employees can focus on customer service, improving overall guest experience while controlling labor costs.

- Brand Perception: The visible presence of robotic cleaning equipment in dining and service areas can increase customer confidence because it reassures them that hygiene is a top priority. A recent study highlighted by Simon-Kucher & Partners found that restaurant sanitation standards now influence consumer purchase behavior more than menu price, and consumers are willing to spend twice as much at restaurants that meet cleanliness standards compared to those that do not.

Leading the Robotic Cleanliness Revolution

A growing number of restaurant chains and companies are already introducing robotics into their kitchens and reaping the benefits. Here are a few examples:

- White Castle has deployed robots to automate burger and fry cooking in its kitchens.

- Wendy’s is using a robot fry cook that can fry French fries with precision and consistency (like the one pictured here), reducing cooking time by 50%.

- Chipotle is testing an autonomous kitchen assistant that uses AI to make and season tortilla chips.

- Sweetgreen has seen improvements in throughput, order accuracy, and labor turnover with its robotic kitchen program developed through M&A.

- BurgerBots in Los Gatos, CA, in partnership with ABB Robotics, uses advanced robots to maintain strict hygiene standards in food prep areas, reducing the risk of cross-contamination and ensuring compliance with FDA and CDC guidelines

- Bluestone Lane, an Australian-inspired coffee concept with 65 locations across the country, is installing sanitization products that use UVA, UVC and Far-UVC 222 light to continuously sanitize indoor environments.

These companies are experiencing a range of benefits from their robotics implementations, including increased efficiency, reduced labor costs, improved food quality and consistency, and enhanced customer satisfaction. These examples illustrate how robotic solutions can be scaled across multiple locations, delivering consistent safety and hygiene results.

Challenges, Compliance, and Best Practices

While the benefits are clear, businesses must address several challenges to leverage robotics fully:

- Investment: Robotic cleaning systems can cost between $10,000 and $50,000, but long-term labor and regulatory compliance savings often offset upfront expenses. Companies would benefit from partnering with reputable robot manufacturers to ensure all equipment meets ISO and FDA hygienic design requirements.

- Compliance: Adherence to ISO and FDA standards are essential for safe robot operation in food environments. Companies would benefit from incorporating regular safety audits into their protocols and procedures.

- Safety Training: OSHA’s robotics safety guidelines highlight the need for thorough employee training, especially during non-routine tasks like setup and maintenance. Companies would benefit from updating safety training to include safe robot operation, including lockout/tagout procedures.

Looking Ahead

Emerging technologies, such as IoT-enabled robots that monitor cleanliness in real-time, are poised to further enhance compliance with federal safety regulations and industry guidelines. These systems can instantly alert managers to sanitation issues, ensuring continuous adherence to safety protocols and reducing the risk of costly violations.

As consumer expectations for visible hygiene measures continue to rise, businesses that embrace robotic cleanliness will stand out in a crowded market. A 2021 survey by Technomic found 89% of diners said having employees visibly cleaning/sanitizing makes them feel safer, making robotic cleaning a competitive advantage.

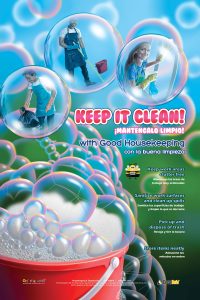

Innovation and Safety with CrewSafe

This spirit of innovation is the way we approach safety at CrewSafe. Just as robotic cleanliness is redefining what it means to operate a safe and efficient business, CrewSafe redefined employee safety training with our Off The Wall® safety awareness posters. Check them out and learn more about how to protect your employees and improve workplace safety.

Sources

- Occupational Safety and Health Administration. (1987). Guidelines for robotics safety. https://www.osha.gov/enforcement/directives/std-01-12-002

- Occupational Safety and Health Administration. (2023). Sanitation standards (29 CFR 1910.141). https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.141

- Tennant Company. (n.d.). Safety Considerations for Robotic Cleaning Machines. https://www.tennantco.com/en_us/resources/resource-center/articles/safety-considerations-for-robotic-cleaning-machines.html

- Food Manufacturing. (2021). Robotic Washdown in Food-Handling Environments. https://www.foodmanufacturing.com/facility/blog/21563308/robotic-washdown-in-foodhandling-environments

- BugerBots. n.d.). Website. https://www.burgerbots.com/ourstory

- DTiQ. (2025). Seven major risks for quick service restaurant franchise owners. https://www.dtiq.com/resources/seven-major-risks-for-quick-service-restaurant-franchise-owners-and-how-to-tackle-them-across-multiple-locations

- Fast Casual.com. (2020) NYC coffee chain installing UVC sanitizing technology. https://www.fastcasual.com/news/nyc-coffee-chain-installing-uvc-sanitizing-technology/

- B2E Automation. (2022). The Robotics Safety Guide for Manufacturers. https://www.b2eautomation.com/insights/the-robotics-safety-guide-for-manufacturers

- National Institutes of Health. (2020). Segmenting areas of potential contamination for adaptive robotic disinfection. https://pmc.ncbi.nlm.nih.gov/articles/PMC7448966/

- USABotics. (n.d.). Industrial Robot Safety Standards and Guidelines. http://www.usabotics.com/osha-safety-standards.htm

- LinkedIn. (2025). OSHA’s 29 CFR 1910.141: The Backbone of Workplace Sanitation. https://www.linkedin.com/pulse/oshas-29-cfr-1910141-backbone-workplace-sanitation-caleb-allen-8y79e

- Robochef.ai. (2025). Robots in the Kitchen: How Automation Can Address 2025 Challenges in the Food Service Industry. https://robochef.ai/blog/robots-in-the-kitchen#:~:text=The%20food%20service%20industry%20is%20navigating%20a%20complex%20landscape%20in,a%20more%20engaging%20dining%20experience

- Simon-Kucher & Partners. (2021, March 9). Recent Study Reveals that Restaurants’ Sanitation Standards Now Influence Consumer Purchase Behavior More Than Price of Menu Items. https://www.simon-kucher.com/en/who-we-are/newsroom/recent-study-reveals-restaurants-sanitation-standards-now-influence-consumer

- Restaurant Business Online. (2022, May 20). Meeting consumer demands for heightened cleanliness and sanitation. https://www.restaurantbusinessonline.com/technology/meeting-consumer-demands-heightened-cleanliness-sanitation