In an era when a minor scratch could lead to sepsis, lacking bandages, antiseptics, or any effective solutions could easily result in death. That reality is now a distant memory, thanks to the remarkable progress of first aid kits. These unassuming containers have evolved from essential battlefield provisions to vital workplace protectors. Join me and explore their journey through time, as they transform into the safety champions we rely on today.

Ancient Roots and Industrial Sparks

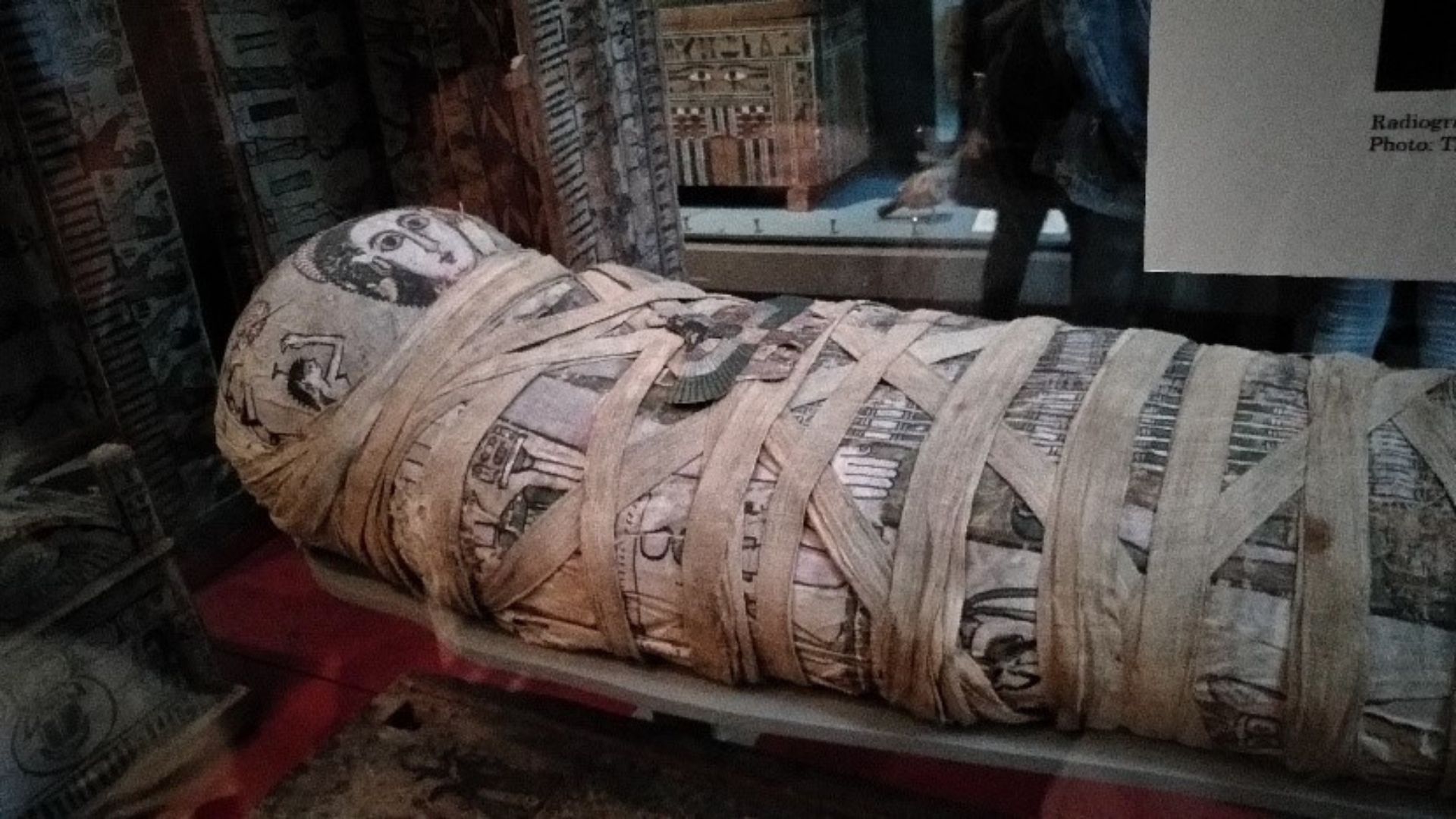

Long before modern regulations, ancient civilizations like the Egyptians and Romans were using linen strips and herbal concoctions to patch up warriors. By the 18th and 19th centuries, military doctors started to organize these medical practices. During the Napoleonic Wars, early make-shift kits were assembled with items like tourniquets and dressings to help keep soldiers in the fight, well, at least breathing, until help arrived.

Then, during the Industrial Revolution, factories seemed to turn into injury hotbeds. New technology and heavy-duty machines were hijacking the workplace, and they didn’t play nicely with the workers. Cuts, burns, and more severe injuries became routine. In 1888, Robert Wood Johnson, co-founder of Johnson & Johnson, stepped up. Inspired by antiseptic pioneer Joseph Lister, he rolled out the first commercial first aid kit for railroad workers. These wooden boxes held sterile gauze, bandages, and a manual. Back then, this was a pioneering solution to a very painful problem.

War’s Big Impact

The need for first aid kits intensified in the 20th century with wars driving the demand. World War I introduced portable kits with iodine and morphine, which were small enough for a soldier’s pack but tough enough for trench warfare. World War II added sulfa drugs and plasma, slashing infection deaths. These wartime wins didn’t stay on the battlefield, though—they seeped into workplaces, showing that fast, effective care worked anywhere.

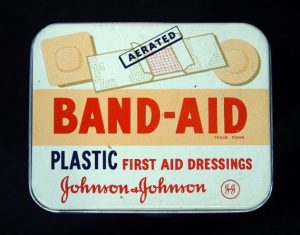

After the wars, industries exploded, and workplace hazards multiplied and diversified. Kits shifted from military morphine to practical gear like adhesive bandages. Band-Aid debuted adhesive bandages in 1920, along with topical antibiotic ointment and creams to soothe and treat burns. By the 1950s, first aid kits focused on keeping workers productive, paving the way for a safety revolution.

OSHA Steps In

In 1970, the Occupational Safety and Health Act created OSHA under the U.S. Department of Labor, making employers accountable for team safety. First aid kits took center stage with 29 CFR 1910.151(b), which requires employers to have “adequate first aid supplies” for their employees and trained personnel if medical help isn’t close by.

What’s “adequate,” you might want to know? OSHA points to the American National Standards Institute’s (ANSI) 1978 Z308.1 standard. It is not law, but it lists essentials like gauze pads, bandages, and scissors, and OSHA sees it as a gold standard. It was revised in 2021, reclassifying tourniquets into Class B kits for high-risk environments, demonstrating that these standards keep pace with current risks and changes in the workplace and beyond.

The evolution continued, and OSHA began to tailor rules to fit industries. For example, 29 CFR 1910.266 demands blankets and large gauze pads for remote logging sites, and 29 CFR 1926.50 calls for construction sites to have weatherproof kits that are checked weekly. Under the U.S. Department of Health and Human Services, NIOSH evaluated the various industry workplaces and their risks to inform and shape these regulations.

Today’s Kit Champions

Modern first aid kits are lean, mean, and workplace-ready. Class A kits tackle minor injuries like paper cuts (no more sepsis!), while Class B kits handle big stuff like lacerations and burns. The CDC encourages gloves for bloodborne pathogen safety. AEDs are even joining the party in more proactive workplaces, zapping cardiac arrest risks.

Labs might add eyewash for chemical spills, while warehouses might stock splints for falls. It’s compliance with a side of caring, and customization rules the day.

Why It’s STILL a Big Deal

Here’s the punchline: First aid kits are workplace MVPs. In 2023, BLS clocked 2.8 million nonfatal injuries—many treatable with a solid first aid kit. They help slash downtime and tell employees they matter. And a safe space builds trust.

Sources

- American National Standards Institute/International Safety Equipment Association. (2021). ANSI/ISEA Z308.1-2021: Minimum requirements for workplace first aid kits and supplies. ANSI.BLOG

- Bureau of Labor Statistics. (2024). Employer-reported workplace injuries and illnesses – 2023. BLS.gov

- Cartwright, M. (2017, June 20). Food & agriculture in ancient Japan. World History Encyclopedia. Ancient_Japan

- Centers for Disease Control and Prevention. (2022). Bloodborne pathogens and needlestick prevention. CDC_NIOSH_BB

- Johnson & Johnson. (n.d.). Badge of safety: The story behind Boy Scout first aid kits. BOY_SCOUT_FA

- National Institute for Occupational Safety and Health. (2023). About NIOSH. Badge_of_Safety

- Occupational Safety and Health Administration. (1998). 29 CFR 1910.151: Medical services and first aid. Med_Services_FA

- Occupational Safety and Health Administration. (2014). 29 CFR 1910.266: Logging operations. Logging

- Occupational Safety and Health Administration. (2019). 29 CFR 1926.50: Medical services and first aid. Med_Services_II

- Occupational Safety and Health Administration. (2003). Automated external defibrillators (AEDs). DEFIB

- Occupational Safety and Health Administration. (2011). 1910.151 Appendix A: First aid kits (non-mandatory). OSHA_First_AID

- Spartan Armor. (2019) A Brief History of Medical Kits. Spar_Brief_History

- Cowdrey, Albert E. & Condon-Rall, Mary Ellen. (1998). Medical Service in the War Against Japan. Medical_services_WWI

- Occupational Safety and Health Administration. (2017). Recording and Reporting Occupational Injuries and Illnesses. OSHA_300_logs